Machineries such as a mini arbor press are definitely helpful when it comes to decreasing the workload and increasing production. Oftentimes, we rely on machines to get things done. In fact, there are a great many kinds of work that can never be finished or completed without the help of a machine. This explains why we seem to be dependent on these machineries to help us with our work. Further, it is such a big deal when it comes to choosing the right kind of machines to help us. Surely, there are countless brands and kinds that are available in the market and selecting appropriate machinery is a serious business. And if you’re looking around for an arbor press or a mini arbor press particularly, we can certainly search for details or facts about this tool or unpowered machine.

An arbor press is a tool which is usually used in precise or detailed work. A lot of machine shops use an arbor press or a mini arbor press to install pistons and wrist pins into piston rods. The clear cut and defined operation of an arbor press, specifically the mini arbor press makes it ideal for precision work. Universal joint replacement and installation into a drive shaft and pressing wheel bearings into axle housings are also jobs reserved for an arbor press operator. If a hydraulic press is good for enormous workload, a mini arbor press is certainly the best choice when it comes to minute or detailed work. Although the regular arbor press is also up to completing a job, if you need to deal with more precise work, then it would be absolutely great to use a mini arbor press for a more thorough result or end product.

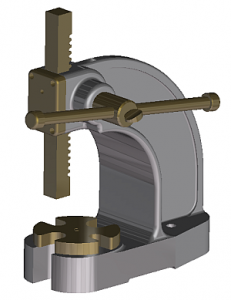

A mini arbor press usually utilizes a hand-operated hydraulic ram mounted inside of steel frame. The ram is pumped and the press exerts pressure against a part. The parts are held in a place against the frame of the press so that they will not move. As the pressure increases, the part eventually succumbs to the pressure and pops free of its mounting location. The new part is pressed in place in the same manner. It is seldom necessary to apply heat to an object in a press, but when heat is required to release an item, use it sparingly.

Without a doubt, a mini arbor press is a very useful tool which saves many hours of beating and pounding with a hammer in doing certain works. The precise action of a small arbor press allows detailed and intricate work to be accomplished in the garage or a home workshop. And by completing some badly needed repairs at home, you can certainly save and conserve resources.

Arbor presses differ in sizes and a mini arbor press is very handy and can be mounted on a table or a workplace without difficulty. Mini arbor press is typically used by jewelers for insertion of precious metals into a small tube or orifice. Truly, an arbor press is a very convenient and useful tool to help us with some handy works at home.

When you talk about the drill press, people think that what you are saying is about arbor press. It is important that you expand your thinking and search for broader details and information about it. You probably need a press which can help you solve your problem. Unfortunately an arbor press might not be your best choice.

When you talk about the drill press, people think that what you are saying is about arbor press. It is important that you expand your thinking and search for broader details and information about it. You probably need a press which can help you solve your problem. Unfortunately an arbor press might not be your best choice.